Smart Cabinet Building

Smart Cabinet Building

To accelerate the digital transformation in control cabinet manufacturing with customized and integrated solutions, Weidmüller, Komax, Zuken, nVent Hoffman / Steinhauer, and Armbruster Engineering have joined forces to launch the Smart Cabinet Building initiative. These companies, technology leaders in various stages of electrical cabinet manufacturing, combine their expertise and know-how within a single ecosystem, focusing on increasing efficiency, flexibility, and quality in production processes.

As the distributor of this innovative solution in Turkey, we support the digital transformation in the sector and help businesses achieve the production standards of the future.

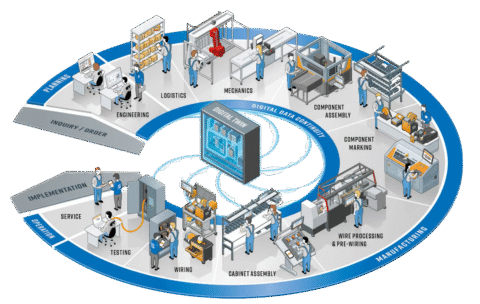

Smart Cabinet Building provides comprehensive solutions to the challenges of control cabinet construction, leveraging network technology and expertise across all process steps. Digital engineering data generated and enhanced by Zuken’s E3 series provides a solid foundation for all aspects of digital manufacturing, assembly, and service.

Benefiting from Digitalization

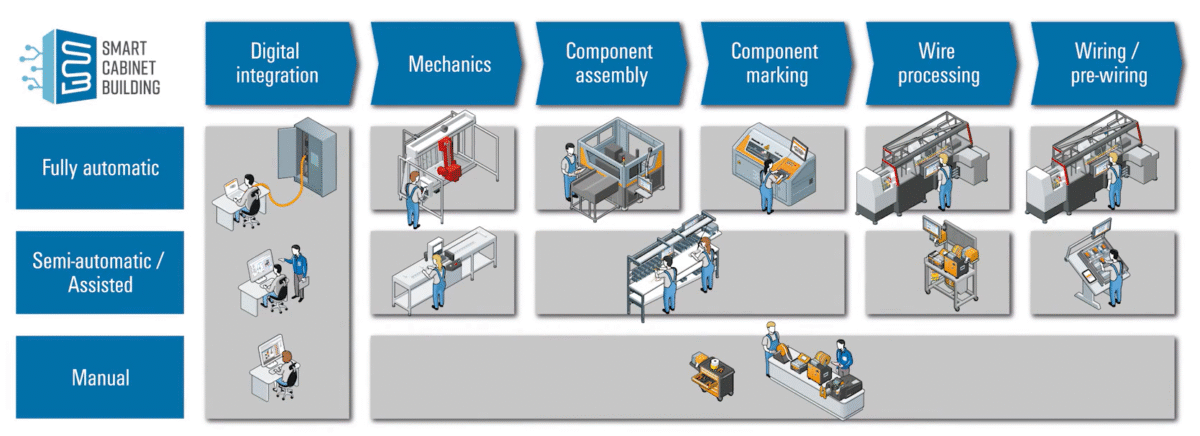

The control panel industry faces many challenges: a wide variety of technical options, rapidly changing customer requirements, cost and pricing pressures, and tight delivery times. Overcoming these challenges requires leveraging automation and digitalization to perfectly combine product, process, and production resources.

Technology and Expertise

Digitalization offers numerous options for optimizing production processes. However, overall efficiency gains can only be achieved when every element of the value-added process is considered. Our goal is to provide comprehensive solutions to today’s and future challenges in control panel manufacturing by combining technology and expertise across all process stages.

Smart and Custom Solutions

Smart Cabinet Building is a consistent and cost-effective solution that meets the individual needs of the control panel industry. It enables the electrical panel manufacturing industry to unlock the potential of digitalization with personalized solutions.

Terminal Strip Configuration

Engineering processes must be completed faster, more precisely, and more efficiently than ever before. Today’s market demands simple and intuitive configuration and ordering workflows. This requires intelligent tools that provide optimal support for complex planning processes.

Weidmüller Configurator is a software solution for selecting, configuring, and ordering terminal rails and terminal rail components from the Weidmüller range. The tool supports continuous engineering workflows from planning to documentation with eCAD systems.

-

Proven configuration designs in true 3D

Use digital product information based on the advanced eCl@ss standard. Complete digital documentation and integrated plausibility and collision checking give you 100% confidence in your configuration.

-

Interfaces for automated production

With further assembly, labeling and wiring with M-Print® PRO, WMC provides all the digital information required for complete process automation.

-

Seamless eCAD Integration

Integrated interfaces enable simple exchange of product data between WMC and common engineering tools such as Zuken E³, EPLAN and others.

Component Collection

The ELAM system provides process control, safe equipment control and complete traceability.

-Perform manual processes safely with the ELAM system.

The ELAM system is a digital production platform that receives data from all connected workstations, provides information, performs support functions and stores process results.

-

Reduce costs

Digital work instructions and assistance systems enable rapid employee training and reduced search times. There’s no need to waste time looking at circuit diagrams or CAD models. Work instructions are automatically derived from digital data, eliminating the need for job preparation. Furthermore, pre-collected order data reduces material logistics time. With the ELAM system, downtime is reduced, which in turn reduces costs.

-

Reduce errors

Important information and the location of terminals and components are reflected directly on the product. Pick to Light controls the correct component picking. Picking is detected manually or automatically by a sensor. The ELAM system monitors the selected parts to prevent the use of incorrect parts. Connected tools are controlled and monitored, and process results are automatically recorded. Overall, rework is prevented and errors are reduced.

-

Flexible production

The ELAM system helps achieve flexible production through type-specific work instructions and process monitoring. Even small, variable orders with batch sizes of up to 1 can be processed quickly, efficiently, and safely. Traceability is ensured through automatic data recording. This not only reduces your effort but also allows you to order efficiently, with increased product quality and economy.

Control Panel Design

Zuken E3.series is a software solution for true concurrent engineering.

Click here to see the details of E3.series

Single Item and Series Production with CE 4.0 Software

The CAD software is based on both DXF and DWG, allowing easy import of existing drawings or creation of superstructure drawings by drag and drop.

Optimizes one-off and mass production with CE 4.0 software.

DXF and DWG-based CAD software allows for the import of existing drawings or the drag-and-drop creation of assembly drawings. Thanks to the integrated CAD software and extensive symbol library, even complex drawings can be quickly created in-house or directly on the machine.

Modification of Control Cabinets

nVent HOFFMAN and Steinhauer are joining forces and continuously expanding their product range: In addition to cabinets, the joint product range now includes automation solutions that provide maximum efficiency, precision, and flexibility.

Modify control cabinets with Modcenter

Precise automation for holes and cutouts shortens lead times and increases profitability

- Modification equipment for panel manufacturers allows for quick modification of in-stock products for fast shipping

- Fast processing of a variety of materials, including mild steel, stainless steel, copper, aluminum, fiberglass, and thermoplastics

- Shorter lead times for customers and lower costs for panel manufacturers

Cutting Cable Ducts and DIN Rails to Length

Take Control. Gain Advantage. By importing your pre-created mounting panel layout drawings into the machine software, NC-Cut provides a simplified cut list and easily guides you through the cuts.

NC-Cut simplifies cable duct and DIN rail preparation.

- NC-Cut combines two processes in a single machine. The first cutter is used to cut the cable duct, while the second cutter is used to cut the DIN rail and busbar.

- Motorized stops guide the material through the cutters, eliminating the need for manual measurement.

- Each cut piece has a printed label to ensure correct placement on the mounting panel.

- High-quality cutters ensure precise cuts and long tool life.

Automated Rail Assembly

The Klippon® Automatic Rail Assembly System, combined with Weidmüller Configurator (WMC), enables fully automated assembly of terminal rails. Using the automated system eliminates the need to select, assign, and position individual terminals. As a result, time savings of up to 60% can be achieved during the assembly process, even greater when considering unmanned operation, which can take up to 7 hours.

- The Klippon® Automatic Rail Assembly System offers significant optimization potential. It enables up to 60% faster assembly with 100% planning reliability.

- Its innovative design approach ensures ease of use thanks to universal cartridges, resulting in significant productivity increases.

- Using Weidmüller Configurator (WMC), the consistent use of data from eCAD programs prevents incorrect assembly.

Competitive advantages with innovative technology

With the Klippon® Automatic Rail Mounting Device, selecting, assigning, positioning, installing, and displaying individual terminal blocks is a thing of the past. Designed with different conditions and starting conditions in mind, the Klippon® Automatic Rail Mounting Device saves up to 60% of your time.

Auxiliary Terminal Strip Installation

ELAM software creates agile and flexible production processes where employees are always guided.

Component Mounting

Terminals and components that cannot be automatically mounted on the rail are manually added using the ELAM system. The ELAM assistant guides the worker through the assembly process and displays necessary information, such as part numbers, on the screen. The terminal’s position on the mounting rail is directly reflected on the product. The data required for work instructions is automatically obtained from the digital configuration.

ELAM controllers allow you to connect electronic devices to the system. This allows you to guide, monitor, and document assembly processes. The ELAM system provides cost-effective yet safe manual assembly of your assembly rails.

Final Assembly

The ELAM system guides and supports workers during the assembly of the electrical panel and other components. The final product image completes the assembly. The production data generated by the assembly plate is transferred to the enclosure’s product lifecycle archive.

This ensures full traceability for each electrical panel. All data can be viewed on the ELAM web server. In addition to numerous evaluation options, the ELAM web server also offers data export to Microsoft Excel for further processing.

Component Picking

The ELAM system enables the picking of key components according to order. The worker is guided by the mobile ELAM assistant, and picking is done manually or by scanning. Connecting to the Pick-to-Light system also minimizes search times.

The order sequence in the ELAM Sorter is pre-planned, ensuring workers are always provided with the correct components in the desired order. This saves time in material preparation and ensures a smooth order flow.

Mounting Plate Assembly

Mounting plate assembly requires the delivery of prepared wiring harnesses, fully assembled mounting rails, and other components. All components are assembled in a systematic order, and the correct component placement location is mapped directly onto the mounting plate by the ELAM assistant. Electrical devices can be controlled and monitored.

For digital work instructions, the component list is transferred directly from the circuit diagram to the ELAM system. This enables guided assembly without any preparatory work.

Fully automated marking

Value-added processes need to be faster, more precise, and more economical, especially during periods of high demand and a growing shortage of specialists. This is particularly true in control panel construction. Digitalization and automation are key factors for increasing efficiency.

In combination with the Weidmüller Configurator (WMC) software, the Klippon® Automated RailLaser enables fully automated marking of pre-assembled terminal strips. Using pre-installed terminal blocks with markers eliminates the need to separate, assign, and mount individual markers. This saves up to 90% of the marking process time. Laser marking terminal strips also meets the highest demands for marking quality.

- The Klippon® Automated Rail Laser offers significant optimization potential. It enables marking up to 90% faster with 100% planning reliability.

- When using the Weidmüller Configurator (WMC), incorrect markings are prevented thanks to the consistent use of data from eCAD programs.

- Innovative technologies and a high-quality laser source ensure precise marking results on a wide range of materials and carrier rail lengths of up to 1.20 metres.

Manual Marking

Labeling systems are a fast and efficient way to produce general-purpose labels, as well as markers for connectors, wires, cables, and devices. M-Print® PRO software allows you to mark your electrical equipment quickly and easily, ensuring your marking needs are professionally designed, printed, and ordered quickly. Borders, barcodes, graphics, and photos can also be easily integrated.

Numerous data conversion routines offer fast and flexible options for data integration. Weidmüller PrintJet CONNECT and thermal transfer printers are available for printing with the THM MultiMark and THM MultiMark PLUS.

Systematic Marking

- Intuitive to use and tailored to your needs. M-Print® PRO software makes it easy to import, edit, and manage data.

- Constructive solutions for all control panel-related applications. From heat shrink tubing to metal pens.

- Ink or thermal transfer – industrial printing systems for every need. Designed with an eye on the future.

Control Panel Design

Zuken E3.series is a software solution for true concurrent engineering.

Automatic Cable Processing

Komax – a leader in its field today and in the future

As a pioneer and market leader in automatic cable processing, Komax offers its customers innovative and sustainable solutions for all situations requiring precise contact connections. Komax manufactures series and custom-made machines for various industries, suitable for all types of automation and customization. A range of high-quality tools, test systems, and intelligent network solutions complete the portfolio and ensure safe and efficient production.

The Komax Group employs more than 3,400 people worldwide and provides sales and service support through subsidiaries and independent agents in over 60 countries.

Your Benefits with Komax

- Scalable solutions for every customer size and process requirement

- Learn from numerous successful customer projects for your project

- The resulting productivity gains open up new opportunities for your projects

Centralized Wire Processing

Parallel processing instead of sequential processing saves 65% on processing time.

Specialization and automation enable reduced working time at all process steps. With a central data source, you can pre-produce materials, thus parallelizing work steps and significantly reducing production times.

In a typical control panel project, time savings of up to 80% can be achieved in wiring, and a 65% reduction in total delivery time.

Length Determination and Data Enrichment

Data from the digital twin

Connection lengths are calculated directly in E-CAD from the 3D structure. Contact type information is obtained from component data. Cable sequence and bundling are transferred directly to the Komax machine.

Closing data gaps

If connection lists are missing, they can be completed in Komax’s own software. Even the length can be determined later via virtual cabling.

An elegant way to determine the length if the 3D structure is missing…

Fully Automatic Labeling of Wires or Tubes

Thanks to fully automatic labeling using inkjet or tube marking modules, each wire is accurately and completely labeled. This minimizes errors during assembly. It is customized, automated, and requires no additional time.

Semi-Automatic Processing

Minimize errors and increase efficiency during the planning and installation phases of panel manufacturing.

According to the “Panel Building 4.0” study conducted by the Institute for Control Engineering of Machine Tools and Manufacturing Units at the University of Stuttgart, 72% of the working time during the installation phase is spent on cabling and mechanical assembly.

The Weidmüller Cable Processing Center (WPC) addresses precisely these problems. Software-controlled, semi-automatic cable assembly significantly speeds up production processes while ensuring the highest quality standards.

Increase the efficiency of your production process by up to 80%

- The use of automated machines reduces processing times, thus contributing to an overall increase in production process efficiency.

- In the systems approach, individual components of the WPC can be removed from the processing sequence or used independently in their own functions.

- Consistently high quality with the use of semi-automatic machines.

Comparison of Cable Assembly Solutions

The market offers panel manufacturers a wide range of cable assembly solutions, from manual to fully automated. Participants in the “Panel Construction 4.0” study found that the greatest potential for improvement and savings lies in solutions targeting cable standardization and pre-assembly, particularly during the installation phase.

The Weidmüllers Cable Processing Center meets all these criteria and more. For a moderate investment, panel manufacturers have obtained a semi-automatic solution with a modular concept. This solution can be easily integrated into existing production processes while providing maximum flexibility. Furthermore, panel manufacturers benefit from reduced time and excellent quality results.

Supported Mounting Plate Assembly

With the ELAM system, the worker is also provided with support in assembling the mounting plate and mounting it to the enclosure.

Final assembly

The ELAM system guides and supports the worker during the assembly of the electrical panel and other components. The final product image completes the assembly. The production data generated by the assembly plate is transferred to the enclosure’s product lifecycle archive. This ensures full traceability for each electrical panel. All data can be viewed on the ELAM web server. In addition to numerous evaluation options, the ELAM web server also offers data export to Microsoft Excel for further processing.

Wiring Assistance

E3.WiringCockpit provides digital support for wiring the control panel.

Digitally Supported Control Cabinet Wiring

E3.WiringCockpit provides digital support for control cabinet wiring on a portable terminal device. The wiring path in the control cabinet is highlighted, providing the user with all necessary additional information. Each wiring connection can be confirmed complete with a single click, and the next cable is displayed. The wiring process is fully documented. In the event of an interruption, work can be continued from the same point.

Digitally Assisted Commissioning

E3.WiringChecks supports the testing of machines, vehicles, or control cabinets during the commissioning phase.

Verification of fully wired cabinets

E3.WiringChecks supports the testing of a fully wired machine, vehicle, or control cabinet during or before commissioning. Results can be documented as part of the E3 data record. Error descriptions are accessible to all relevant departments, from engineering to production, and assigned issues can be accessed and addressed. This allows error correction and follow-up checks to be performed in a controlled manner.

BROCHURES

VIDEOS